Nanoindentation provides a promising approach for characterizing geomechanical properties when large samples, such as core plugs, are unavailable. However, common models for its interpretation are limited to simple (ideal) patterns that are absent in subsurface samples, as shown by more than 10,000 tests conducted in our group. This research focuses on the interpretation of complex fractures.

1. Conceptual Model Based on the Effective Medium Theory

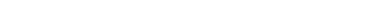

This approach determines fracture toughness based on the assumption that the matrix consists of two intertwined solid domains. One domain is weaker and fails under load, resulting in fractures, while the other remains intact. Consequently, nanoindentation characterizes the relevant properties of the weaker domain, which are then converted to fracture toughness using the effective medium theory. This approach accounts for sample heterogeneity and encompasses various scenarios. For instance, nanoindentation does not create a fracture if the tip lands on a grain within the stronger domain. Only a fraction of indentations results in fractures, which are analyzed to characterize fracture toughness.

2. Equivalent-Area Approach Based on K-Means Clustering

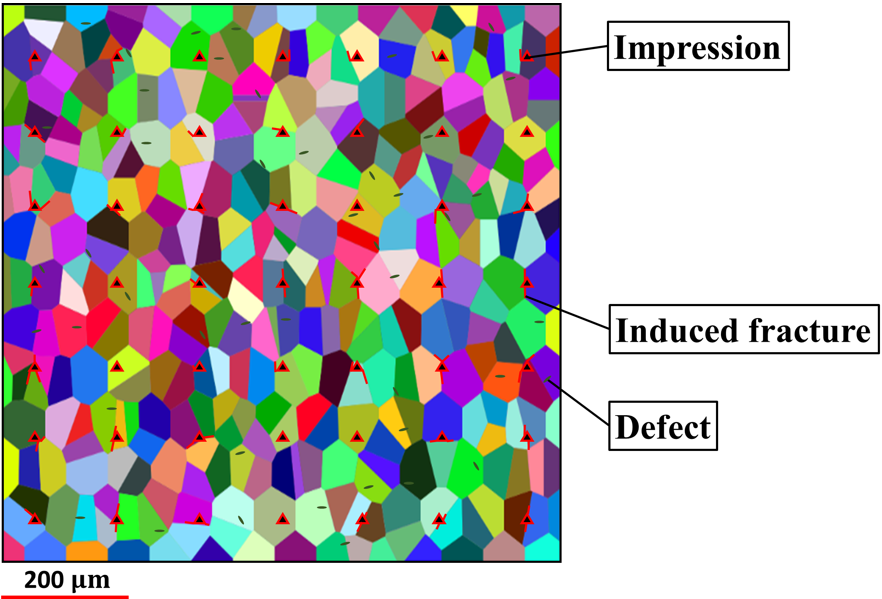

This approach first divides the image with the complex pattern (Fig. 3a) into intact, damaged, and impression regions (Fig. 3b). It then calculates the total area of the impression and damaged regions to form an equilateral triangle with an equivalent area. Next, it sets the crack length to two-thirds of the triangle’s height (Fig. 3c). Finally, it uses the estimated crack length, along with the elastic modulus and hardness, to characterize fracture toughness.

3. Deep Learning for Characterizing Fracture Toughness

This approach employs deep learning to predict fracture toughness from nanoindentation images. A deep-learning model, incorporating a pretrained VGG16 and fully connected layers, analyzes 21,276 images generated by augmenting 3,546 original images. The model uses the Adam solver with a learning rate of 0.0002 and a batch size of 32, both fine-tuned for optimal performance. It determines normalized fracture toughness with a mean squared error of 0.0014, demonstrating the model’s capability to interpret underlying features effectively.

Representative articles

- Esatyana, E., Alipour, M., and Sakhaee-Pour, A. (2021). Characterizing anisotropic fracture toughness of shale using nanoindentation. SPE Reservoir Evaluation & Engineering.

- Alipour, M., Esatyana, E., Sakhaee-Pour, A., Sadooni, F., and Al-Kuwari, H. (2021). Characterizing fracture toughness using machine learning. Journal of Petroleum Science and Engineering, 200, 108202.

- Sakhaee-Pour, A. (2025). Deep learning for characterizing fracture toughness from the nanoindentation image of a complex heterogeneous medium. Theoretical and Applied Fracture Mechanics, 135, 104759.

- Sakhaee-Pour, A. (2025). Deep learning for interpreting elastic modulus and hardness from complex fractures. Engineering Fracture Mechanics, 320, 1111074.