Our laboratory is designed specifically to conduct high-precision measurements in rock physics where petroleum engineering interfaces with nanofluidics and with nanomechanics, with an emphasis on shale and carbonate formations. Our work is combined with measurements conducted at other locations. The standard measurements, conducted on core plugs or blocks, are used to test our results, but they are not the main focus of our research.

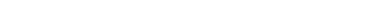

Nanoindenter: the nanomechanical actuator is a force-generation mechanism with a displacement sensor. An integrated video-microscope is included with an 800 x optical microscope and digital zoom (displacement range: 80 micrometers; displacement resolution: 0.04 nm; typical noise < 0.25 nm; load application: coil/magnet; maximum load: 1 N; load resolution: 6 nN; loading column mass: < 5 g; typical indenter normal stiffness: 200 N/m; damping coefficient: 0.1 N.s/m; resonant frequency: 15 Hz; data acquisition rate: 100 kHz).

Nanoindenter: the nanomechanical actuator is a force-generation mechanism with a displacement sensor. An integrated video-microscope is included with an 800 x optical microscope and digital zoom (displacement range: 80 micrometers; displacement resolution: 0.04 nm; typical noise < 0.25 nm; load application: coil/magnet; maximum load: 1 N; load resolution: 6 nN; loading column mass: < 5 g; typical indenter normal stiffness: 200 N/m; damping coefficient: 0.1 N.s/m; resonant frequency: 15 Hz; data acquisition rate: 100 kHz).

Multiport physisorption analyzer: the device is fully automated and has three stations allowing for different analyses with high accuracy. It determines the intertwined relationships among the surface area, pore volume, release evaluations, and capacity. The measurement will help us to gain valuable insight into the structural and chemical heterogeneity’s influence on adsorption dynamics. The device reports the isotherm, BET surface area, Langmuir surface area, t-plot, BJH adsorption and desorption, and pore-size distributions calculated by alpha-s method, DFT, and the Dubinin–Radushkevich method.

Multiport physisorption analyzer: the device is fully automated and has three stations allowing for different analyses with high accuracy. It determines the intertwined relationships among the surface area, pore volume, release evaluations, and capacity. The measurement will help us to gain valuable insight into the structural and chemical heterogeneity’s influence on adsorption dynamics. The device reports the isotherm, BET surface area, Langmuir surface area, t-plot, BJH adsorption and desorption, and pore-size distributions calculated by alpha-s method, DFT, and the Dubinin–Radushkevich method.

The Autopore V is based on mercury intrusion into a porous medium under stringently controlled pressures. It is capable of measuring pore diameters from 3 nm to 1100 microns by increasing the capillary pressure up to 60000 psia. The pressure increments can be as fine as 0.05 psia. It allows us to calculate various properties, such as pore-throat size distribution, total pore volume, total pore surface area, and sample densities (bulk and skeletal). It also offers data reduction and reporting choices that provide more information about pore geometry and the transport properties. In addition, it has a quick-scan mode that allows a continuous pressure increase, approximating equilibrium and providing faster screening. It is also equipped with a correction routine for baseline (automatic, differential, or manual) to produce greater accuracy by correcting for compressibility and thermal effects caused by high pressure.

The Autopore V is based on mercury intrusion into a porous medium under stringently controlled pressures. It is capable of measuring pore diameters from 3 nm to 1100 microns by increasing the capillary pressure up to 60000 psia. The pressure increments can be as fine as 0.05 psia. It allows us to calculate various properties, such as pore-throat size distribution, total pore volume, total pore surface area, and sample densities (bulk and skeletal). It also offers data reduction and reporting choices that provide more information about pore geometry and the transport properties. In addition, it has a quick-scan mode that allows a continuous pressure increase, approximating equilibrium and providing faster screening. It is also equipped with a correction routine for baseline (automatic, differential, or manual) to produce greater accuracy by correcting for compressibility and thermal effects caused by high pressure.

Surface polisher and grinder: the automatic, microprocessor-controlled machine for grinding and polishing of specimens on a 250-mm MD-Disc with a cone (removal depth: 50 – 5000 micrometer; disc: 40–600 rpm; head: 50–150 rpm; specimen holder: 30–300 N; noise level: 47 dBA at idle running, 54 dBA at polishing, and 56 dBA at grinding).

Surface polisher and grinder: the automatic, microprocessor-controlled machine for grinding and polishing of specimens on a 250-mm MD-Disc with a cone (removal depth: 50 – 5000 micrometer; disc: 40–600 rpm; head: 50–150 rpm; specimen holder: 30–300 N; noise level: 47 dBA at idle running, 54 dBA at polishing, and 56 dBA at grinding).

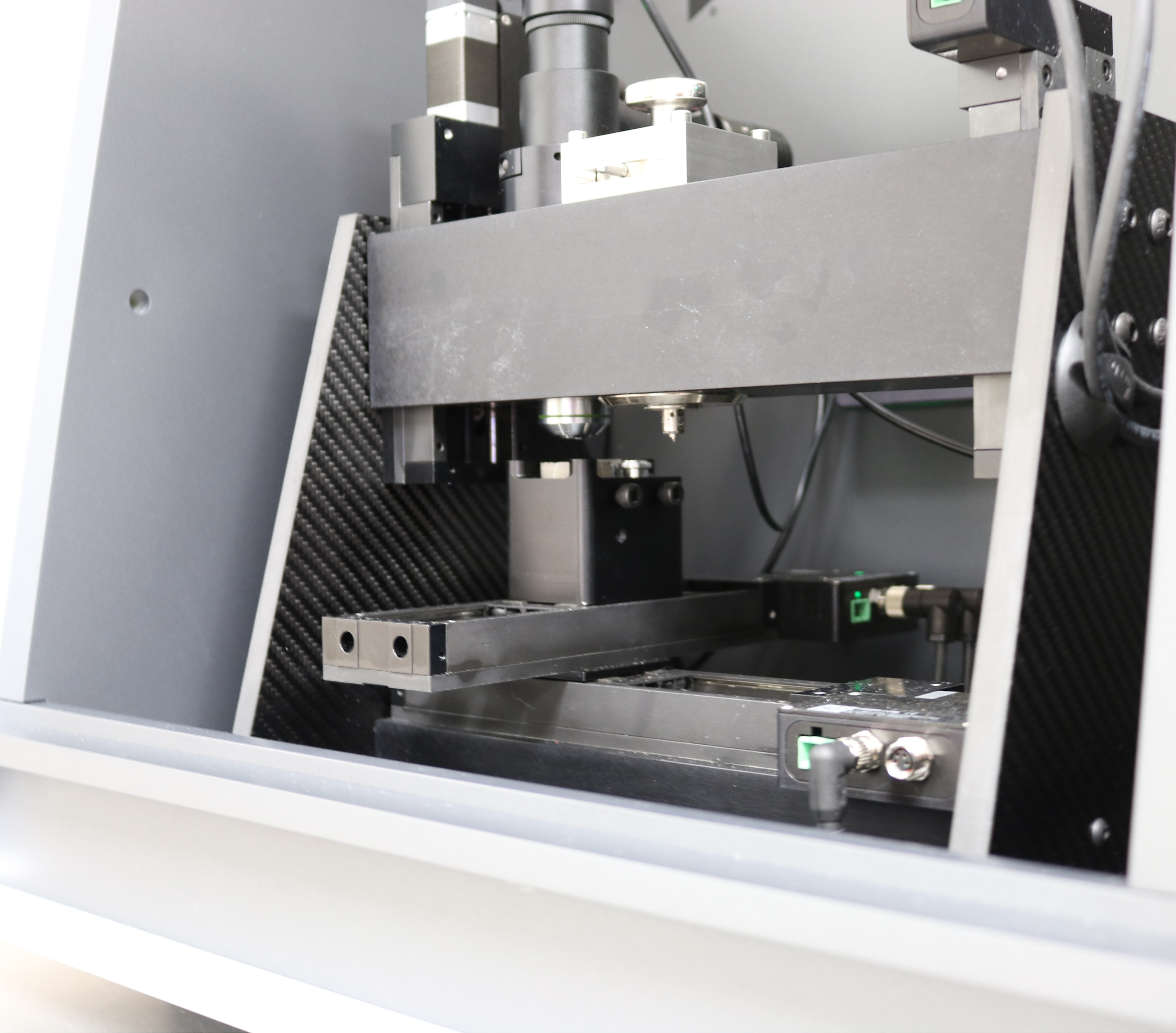

- Optical tensiometer: the device is for fully computer-controlled contact angle, surface and interfacial tension, dynamic contact angle, and surface free energy measurements. Its camera has a nominal imaging speed of 138 fps with a 1984 x 1264 resolution and up to 3009 fps with a 672 x 57 resolution. It includes zoom lens 0.7–4.5 magnification. The software is coded to determine the contact angle by the sessile/rising drop method with automatic baseline detection, the surface/ interfacial tension by the pendant/ rising drop method, the contact angle by the liquid meniscus method, image fitting (polynomial, Basforth-Adams, circular fit, and Young–Laplace including autobaseline algorithm), and the surface free energy.

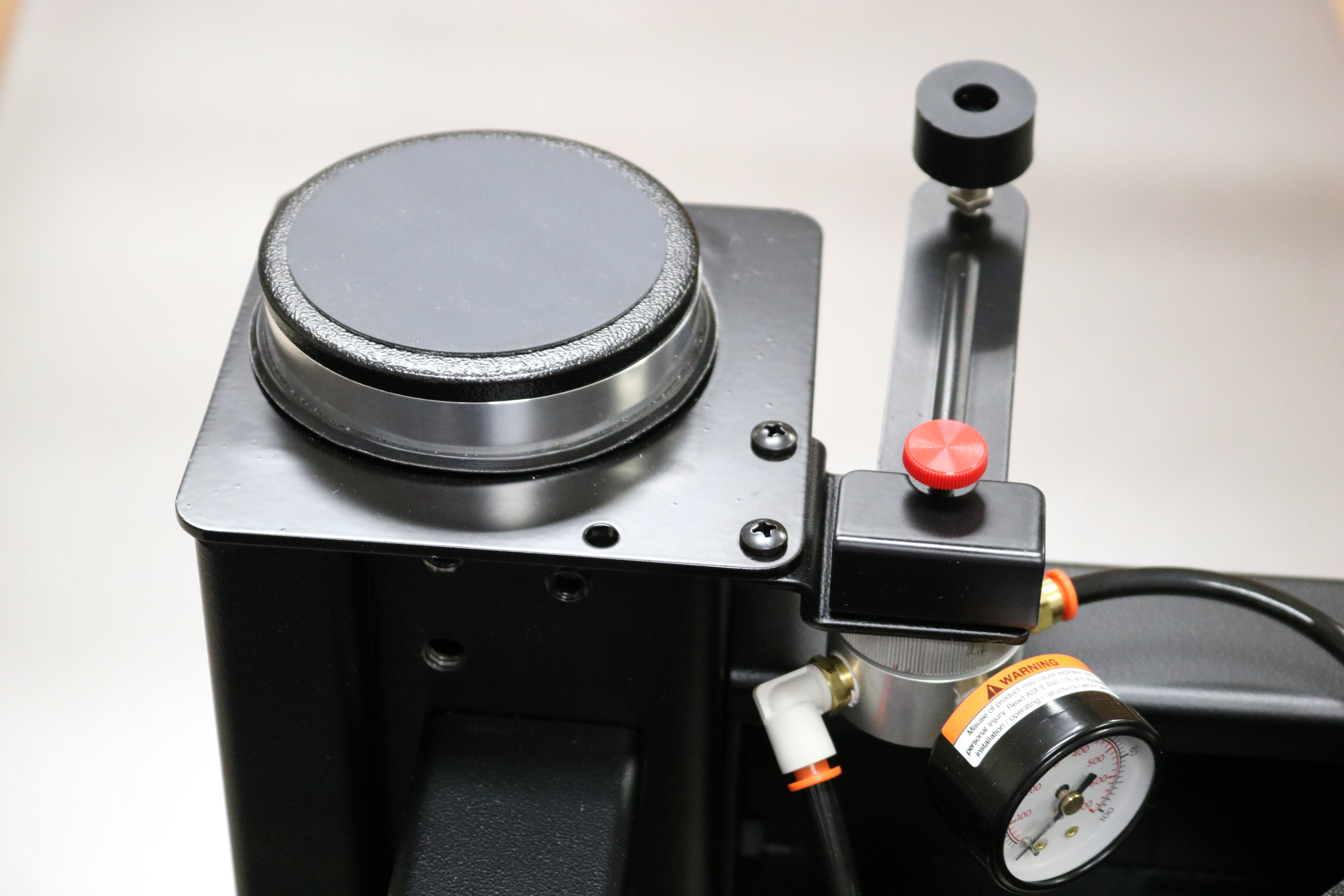

Transient-flow permeameter: the custom-made permeameter is designed for transient conditions and permits corrected permeability measurement of dry or partially saturated samples down to 10 nano-darcies and can be used with any existing core holder capable of a minimum of 1,000 psig pore pressure and a minimum of 1,500 psig confining stress.

Transient-flow permeameter: the custom-made permeameter is designed for transient conditions and permits corrected permeability measurement of dry or partially saturated samples down to 10 nano-darcies and can be used with any existing core holder capable of a minimum of 1,000 psig pore pressure and a minimum of 1,500 psig confining stress.

Steady-flow permeameter: the custom-made permeameter is designed for steady conditions and measures ultra-low permeability down to 10 nano-darcies. It has two core holders and enables us to simultaneously analyze two samples. An advanced algorithm coupled with improvements in computer control allow substantially decreased analytical times to be achieved without a decrease in the accuracy of the measurement. Three to four permeabilities are measured over a range of pore pressures. Making these measurements also provides an ideal opportunity to determine the sample compressibility.

Steady-flow permeameter: the custom-made permeameter is designed for steady conditions and measures ultra-low permeability down to 10 nano-darcies. It has two core holders and enables us to simultaneously analyze two samples. An advanced algorithm coupled with improvements in computer control allow substantially decreased analytical times to be achieved without a decrease in the accuracy of the measurement. Three to four permeabilities are measured over a range of pore pressures. Making these measurements also provides an ideal opportunity to determine the sample compressibility.

Porosimeter: the device allows us to measure the rock sample porosity with helium based on the Boyle’s law. The measured porosity will be representative of the total pore volume, as opposed to the connected porosity.

Porosimeter: the device allows us to measure the rock sample porosity with helium based on the Boyle’s law. The measured porosity will be representative of the total pore volume, as opposed to the connected porosity.

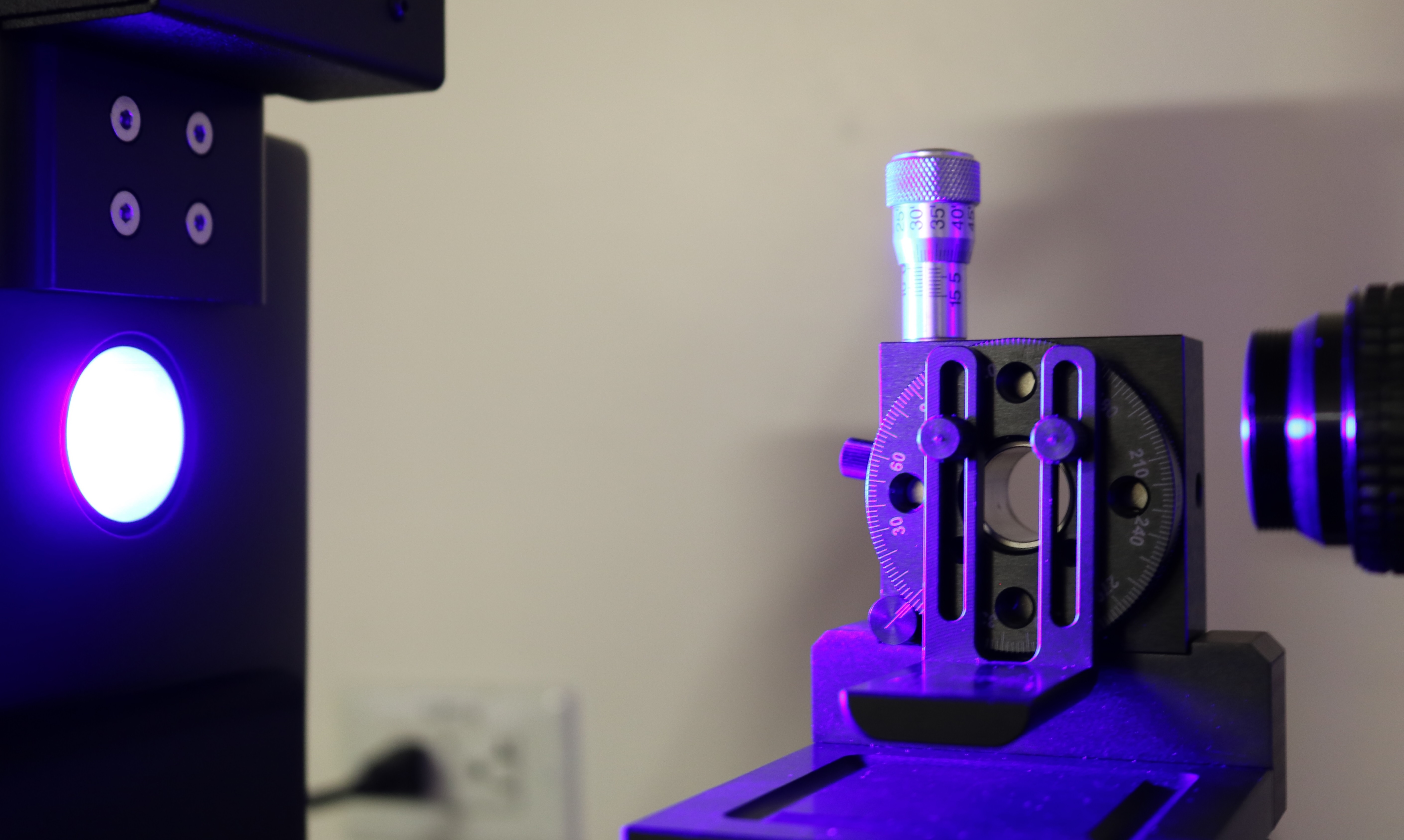

- Precision saw: the sectioning saw is designed for cutting various types of materials with minimal deformation. It features an automatic cutoff switch, a counter-balanced sliding load weight system, 0–500 grams (0–800 grams with accessory weight kit), a built-in inch or metric digital micrometer cross-feed for sample location, and a 1/8 HP DC motor with continuously variable arbor speed, 100–975 RPM (at 25 RPM increments).

CleanBench™ is a vibration-isolation table, which is ideal for a wide variety of applications, including nanoindentation. The low-profile, high-density tops lower the overall floating center-of-mass ensuring inherent stability, even for relatively top-heavy payloads. The vertical and horizontal vibration isolation starts at 2 Hz, and it reduces vibration by more than 95% at 10Hz. The precision model maintains height to ± 0.1 mm (± 0.005 in).

CleanBench™ is a vibration-isolation table, which is ideal for a wide variety of applications, including nanoindentation. The low-profile, high-density tops lower the overall floating center-of-mass ensuring inherent stability, even for relatively top-heavy payloads. The vertical and horizontal vibration isolation starts at 2 Hz, and it reduces vibration by more than 95% at 10Hz. The precision model maintains height to ± 0.1 mm (± 0.005 in).

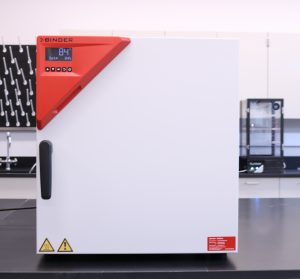

Binder Drying Oven: the heating oven is required for rock sample preparation. It allows us to apply a wide range of temperature and provides a high standard of quality and process stability, whether by gravity or mechanical convection.

Binder Drying Oven: the heating oven is required for rock sample preparation. It allows us to apply a wide range of temperature and provides a high standard of quality and process stability, whether by gravity or mechanical convection.